Engineering Service

Vapor Recovery Unit (VRU)

During storage, light hydrocarbons dissolved in the crude oil or condensate—including methane and other volatile organic compounds (VOC), natural gas liquids(NGLs), hazardous air pollutants (HAP), and some inert gases—vaporize or "flash out" and collect in the space between the liquid and the fixed roof of the tank. As the liquid level in the tank fluctuates, these vapors are often vented to the atmosphere.

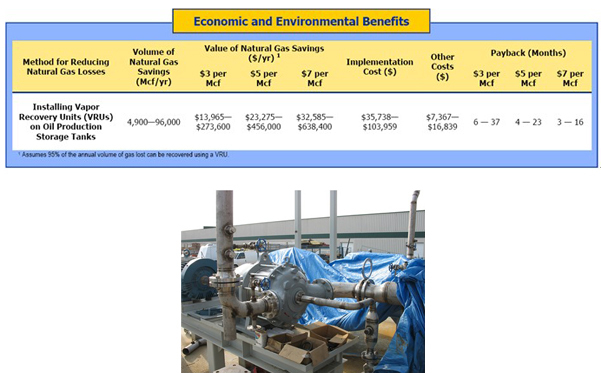

One way to prevent emissions of these light hydrocarbon vapors and yield significant economic savings is to install vapor recovery units (VRUs) on storage tanks. VRUs are relatively simple systems that can capture about 95 percent of the Btu-rich vapors for sale or for use onsite as fuel. Currently, between 7,000 and 9,000 VRUs are installed in the oil production sector, with an average off our tanks connected to each VRU.

Partners have found that when the volume of vapors is sufficient, installing a VRU on one or multiple storage tanks can save up to $606,800 per year and pay back in as little as two months. This Lessons Learned study describes how partners can identify when and where VRUs should be installed to realize these economic and environmental benefits.

During storage, light hydrocarbons dissolved in the crude oil or condensate—including methane and other volatile organic compounds (VOC), natural gas liquids(NGLs), hazardous air pollutants (HAP), and some inert gases—vaporize or "flash out" and collect in the space between the liquid and the fixed roof of the tank. As the liquid level in the tank fluctuates, these vapors are often vented to the atmosphere.

One way to prevent emissions of these light hydrocarbon vapors and yield significant economic savings is to install vapor recovery units (VRUs) on storage tanks. VRUs are relatively simple systems that can capture about 95 percent of the Btu-rich vapors for sale or for use onsite as fuel. Currently, between 7,000 and 9,000 VRUs are installed in the oil production sector, with an average off our tanks connected to each VRU.

Partners have found that when the volume of vapors is sufficient, installing a VRU on one or multiple storage tanks can save up to $606,800 per year and pay back in as little as two months. This Lessons Learned study describes how partners can identify when and where VRUs should be installed to realize these economic and environmental benefits.

Company Profile | Engineering Services | Products | Contact

Address:26 Sunpark Plaza Southeast, Calgary, Canada Email: info@apec-inc.com

Address:26 Sunpark Plaza Southeast, Calgary, Canada Email: info@apec-inc.com